Calibration & Inspection Services UAE

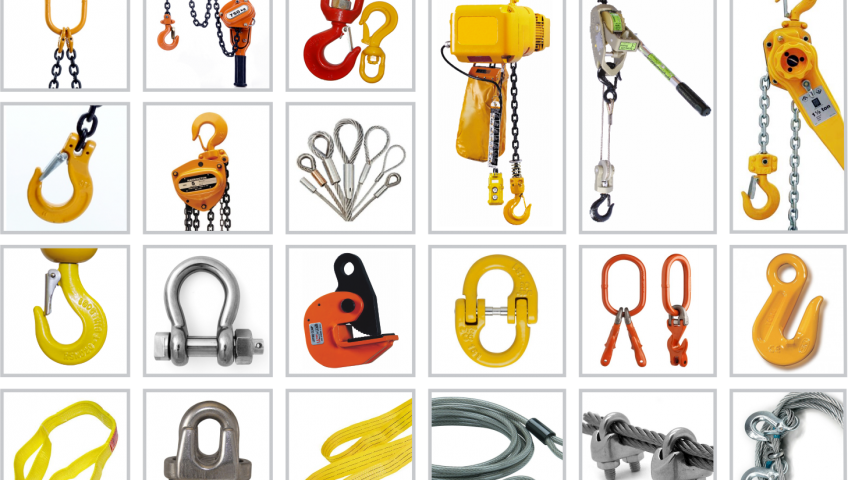

World Wide Inspection and Calibration Services Est is a UAE based company specialized in the field of Lifting & Material handling Equipment, instrumentation & control related to oil, gas, power, water, petrochemical and processing industry. We use machines and equipment on a regular basis be it at work or at home. To work efficiently we need to keep on monitoring the performances of the equipment and machine we use both in our personal or professional life. The regular calibration and inspection are important to gauge the accuracy of the instrument we use. Most of the big companies and groups often rely on competent calibration and inspection services UAE to make sure that the machines are working in a right order as per the specifications of the manufacturers. In any industry, the accuracy is very critical to maintain the regular process operations and thus to avoid the running afoul of local, federal and regional compliance laws.

What are Calibration Services?

If you are looking for calibration companies in Abu Dhabhi or in UAE, you have reached at the right place. WorldWideICS one of the most reliable groups that offer a wide range of Calibration Services. Our facilities are fully accredited to the national standards. We render cost-effective services that covers all the critical measuring points. These services are performed by specialist and highly trained staff of our organization. A comprehensive database of standard operating procedures ensures the professional execution of our services.

If you are looking for calibration companies in Abu Dhabhi or in UAE, you have reached at the right place. WorldWideICS one of the most reliable groups that offer a wide range of Calibration Services. Our facilities are fully accredited to the national standards. We render cost-effective services that covers all the critical measuring points. These services are performed by specialist and highly trained staff of our organization. A comprehensive database of standard operating procedures ensures the professional execution of our services.

Our services are explained below:

Calibration Services, Calibration Laboratory, Dimension Calibration Services, Electrical Calibration Services, Pressure Calibration Services, Temperature Calibration Services, Calibration Laboratory For Measuring Instruments, Calibration Laboratory For Electrical Instruments, Calibration Laboratory For Temperature Instruments, Calibration Laboratory For Pressure Instruments, Calibration Laboratory For Dimensional Instruments, Calibration of Equipments, Measuring Instrument Calibration, Electrical Instrument Calibration, Mechanical Instrument Calibration, Electronic Instrument Calibration, Thermal Instrument Calibration, Chemical Instrument Calibration, Laboratory Instrument Calibration, Laboratory for Calibration, Industrial Instrument Calibration, Calibration of Industrial Instruments, Services, Abu Dhabi, U.A.E.

Calibration Services, Calibration Laboratory, Dimension Calibration Services, Electrical Calibration Services, Pressure Calibration Services, Temperature Calibration Services, Calibration Laboratory For Measuring Instruments, Calibration Laboratory For Electrical Instruments, Calibration Laboratory For Temperature Instruments, Calibration Laboratory For Pressure Instruments, Calibration Laboratory For Dimensional Instruments, Calibration of Equipments, Measuring Instrument Calibration, Electrical Instrument Calibration, Mechanical Instrument Calibration, Electronic Instrument Calibration, Thermal Instrument Calibration, Chemical Instrument Calibration, Laboratory Instrument Calibration, Laboratory for Calibration, Industrial Instrument Calibration, Calibration of Industrial Instruments, Services, Abu Dhabi, U.A.E.

Calibration is simple, provided you understand the basics of it. To put in simple words, Calibration is a method of adjusting and evaluating the values of any equipment and gadget for its accuracy and precision when it is compared to other similar equipment or gadget of the accurate and unvarying standard. The calibration checks correct and defines all instruments/equipment, which uses the quantitative measurements so as to make the results are par with the other correct devices. This is the reason why Calibration companies in Dubai have vital roles to play as these help your equipment to perform the best.

Calibration companies in UAE cannot accept shortcut and faulty processes, as critical businesses and people often rely upon the outcome of the measurements, which undergo this process. The engineering, measuring device manufacturers, Laboratories, medical/healthcare, research & development, markets, testing, aviation, manufacturing, processing plants are some of the key businesses, which are seen undergoing the process of calibration. This in turn help in reducing the errors, which can be easily adjusted (through the help of calibration constants) until the output is seen spot-on perfect. The gadgets and equipment that are seen passing the process of calibration program will get the precise recall list of its test, diagnostic and measurement equipment.

Calibration – How It’s Done

The Calibration companies in Abu Dhabi are relatively offering services that depend upon the nature of the devices of equipment, process and instrumentation involved. The professional calibration services carried out by Calibration Companies in UAE often rely on their own calibration expertise and instrumentation which are approved by a certifying, licensed compliance bureau. These groups assure the accuracy of all equipment and instruments as per the set guidelines of the agencies found in the local and international market. The professional instrumentation is often used by calibration companies in Dubai for checking the accuracy under regulated conditions, which end up meeting the compliance bureau guidelines. Calibration is important as it helps the devices and equipment at different engineering and other companies to function and perform as per the norms of the local and international agencies taking care keeping a check over the environment and other factors.

What are Inspection Services?

The term is self explanatory and again if you are looking for quality inspection services UAE, you have landed at a right place. Worldwideics offers a wide range of inspection services that help our customers make the right decisions that involve asset maintenance, plant safety, and sustainable growth. Worldwideics combines cutting-edge nondestructive testing technologies backed with experienced field engineers to provide the analysis you need to choose the most appropriate risk-mitigation path.

The term is self explanatory and again if you are looking for quality inspection services UAE, you have landed at a right place. Worldwideics offers a wide range of inspection services that help our customers make the right decisions that involve asset maintenance, plant safety, and sustainable growth. Worldwideics combines cutting-edge nondestructive testing technologies backed with experienced field engineers to provide the analysis you need to choose the most appropriate risk-mitigation path.

Worldwideics Industrial Solutions designs Inspection Services offers addresses all the tough choices that companies face today. These include balancing cost control and other short-term challenges with the long-term outlook of sustainable growth.

The opportunity to optimize the reliability of your equipment comes from having the confidence in making the right choices first. We bring out the truly cutting-edge technology in the hands of certified technicians to reduce downtime and provide the analysis you need, down to the most detailed level of risk assessment available.

If you look at the different Inspection companies in Abu Dhabi, these simply deal with verifying the number of products, systems or asset conform to the set specified criteria. It covers a number of services that help in reducing the risk, controls the quality and then verifies quantity along with meeting up the regulatory requirements. Any product is usually inspected a number of times during its life cycle to ensure that it is designed and efficiently operated along with meeting the set benchmark for quality and safety. The companies involved in inspection services UAE offer their clients that the products they have installed in their setups comply with the local and international benchmarks and function as per the given requirements. The inspection companies in Abu Dhabi mostly deal with a wide range of products including the Lifting Equipment like cranes, moving equipment, workshop equipment, vehicles, and machines. You can hire companies dealing with inspection services in UAE.

If you look at the different Inspection companies in Abu Dhabi, these simply deal with verifying the number of products, systems or asset conform to the set specified criteria. It covers a number of services that help in reducing the risk, controls the quality and then verifies quantity along with meeting up the regulatory requirements. Any product is usually inspected a number of times during its life cycle to ensure that it is designed and efficiently operated along with meeting the set benchmark for quality and safety. The companies involved in inspection services UAE offer their clients that the products they have installed in their setups comply with the local and international benchmarks and function as per the given requirements. The inspection companies in Abu Dhabi mostly deal with a wide range of products including the Lifting Equipment like cranes, moving equipment, workshop equipment, vehicles, and machines. You can hire companies dealing with inspection services in UAE.

Professional Inspection and Calibration Services For The Home

The need to compete as per the set benchmark seems to be increasing in the market with the passage of time. Hence not many company owners and businessman tend to overlook the importance of their machines and equipment to inspect and calibrate. Thanks to the number of calibration and inspection companies in Abu Dhabi and other places are mushrooming to cater the professional services to business of different type and category. You can take your time to find out the best calibration and inspection services UAE to meet all your requirements. Find one by visiting the site – http://worldwideics.ae.

Ultrasonic meters are rapidly turning into probably the most generally utilized meters in flow measurement. As of now ultrasonic meters are being used to quantify flammable gas, steam, air, water, fluid hydrocarbons, and different liquids. A portion of the real advantages of ultrasonic meters incorporate the analytic capacities, the way that there is no obstruction to the flow stream, and the wide turn down abilities of the meters.

Ultrasonic meters are rapidly turning into probably the most generally utilized meters in flow measurement. As of now ultrasonic meters are being used to quantify flammable gas, steam, air, water, fluid hydrocarbons, and different liquids. A portion of the real advantages of ultrasonic meters incorporate the analytic capacities, the way that there is no obstruction to the flow stream, and the wide turn down abilities of the meters.

Pressure gauges are instruments used to quantify the pressure of fluid or gaseous materials by ascertaining the power they would apply at a condition of rest. The gauge shows the contrast between the pressure in the region being estimated and that of the environment, called the gauge pressure. The absolute or aggregate pressure of the area will be the whole of the pressure contrast estimated by the gauge and the environmental pressure.

Pressure gauges are instruments used to quantify the pressure of fluid or gaseous materials by ascertaining the power they would apply at a condition of rest. The gauge shows the contrast between the pressure in the region being estimated and that of the environment, called the gauge pressure. The absolute or aggregate pressure of the area will be the whole of the pressure contrast estimated by the gauge and the environmental pressure. With years of experience and records of accomplishment, accrediting with high effective performing equipment is the key factor of companies that deliver calibration services in UAE. Teamed up with skilled professionals, calibration & third party inspection services are found equally traceable to National & International standards. Below appending is the list of major key scopes of calibration services in Abu Dhabi, and in & around regions.

With years of experience and records of accomplishment, accrediting with high effective performing equipment is the key factor of companies that deliver calibration services in UAE. Teamed up with skilled professionals, calibration & third party inspection services are found equally traceable to National & International standards. Below appending is the list of major key scopes of calibration services in Abu Dhabi, and in & around regions. Electrical instruments measure the different electrical amounts like electrical power factor, power, voltage and current and so forth. All simple electrical instruments utilize mechanical framework for the measurement of various electrical amounts however as we realize that the all mechanical framework has some inactivity along these lines electrical instruments have a restricted time reaction.

Electrical instruments measure the different electrical amounts like electrical power factor, power, voltage and current and so forth. All simple electrical instruments utilize mechanical framework for the measurement of various electrical amounts however as we realize that the all mechanical framework has some inactivity along these lines electrical instruments have a restricted time reaction. All the measuring instruments for measurement of length, weight, temperature and so forth ought to be calibrated against some standard scale at the consistent interim’s as determined by the producer. There are distinctive strategies or

All the measuring instruments for measurement of length, weight, temperature and so forth ought to be calibrated against some standard scale at the consistent interim’s as determined by the producer. There are distinctive strategies or  Calibration is checking the accuracy of a measurement instrument by contrasting it with reference norms. The effect of equipment calibration is higher accuracy. Electronic calibration is one of three primary kinds of calibration methods utilized today. Different sorts of current calibration method include mechanical and thermal calibration. Electronic calibration manages the calibration of electric and electronic instruments.

Calibration is checking the accuracy of a measurement instrument by contrasting it with reference norms. The effect of equipment calibration is higher accuracy. Electronic calibration is one of three primary kinds of calibration methods utilized today. Different sorts of current calibration method include mechanical and thermal calibration. Electronic calibration manages the calibration of electric and electronic instruments. Calibration of your measuring instruments

Calibration of your measuring instruments

If you are looking for calibration companies in Abu Dhabhi or in UAE, you have reached at the right place. WorldWideICS one of the most reliable groups that offer a wide range of

If you are looking for calibration companies in Abu Dhabhi or in UAE, you have reached at the right place. WorldWideICS one of the most reliable groups that offer a wide range of  Calibration Services, Calibration Laboratory, Dimension Calibration Services, Electrical Calibration Services, Pressure Calibration Services, Temperature Calibration Services, Calibration Laboratory For Measuring Instruments, Calibration Laboratory For Electrical Instruments, Calibration Laboratory For Temperature Instruments, Calibration Laboratory For Pressure Instruments, Calibration Laboratory For Dimensional Instruments, Calibration of Equipments, Measuring Instrument Calibration, Electrical Instrument Calibration, Mechanical Instrument Calibration, Electronic

Calibration Services, Calibration Laboratory, Dimension Calibration Services, Electrical Calibration Services, Pressure Calibration Services, Temperature Calibration Services, Calibration Laboratory For Measuring Instruments, Calibration Laboratory For Electrical Instruments, Calibration Laboratory For Temperature Instruments, Calibration Laboratory For Pressure Instruments, Calibration Laboratory For Dimensional Instruments, Calibration of Equipments, Measuring Instrument Calibration, Electrical Instrument Calibration, Mechanical Instrument Calibration, Electronic  The term is self explanatory and again if you are looking for quality

The term is self explanatory and again if you are looking for quality  If you look at the different Inspection companies in Abu Dhabi, these simply deal with verifying the number of products, systems or asset conform to the set specified criteria. It covers a number of services that help in reducing the risk, controls the quality and then verifies quantity along with meeting up the regulatory requirements. Any product is usually inspected a number of times during its life cycle to ensure that it is designed and efficiently operated along with meeting the set benchmark for quality and safety. The companies involved in inspection services UAE offer their clients that the products they have installed in their setups comply with the local and international benchmarks and function as per the given requirements. The inspection companies in Abu Dhabi mostly deal with a wide range of products including the Lifting Equipment like cranes, moving equipment, workshop equipment, vehicles, and machines. You can hire companies dealing with inspection services in UAE.

If you look at the different Inspection companies in Abu Dhabi, these simply deal with verifying the number of products, systems or asset conform to the set specified criteria. It covers a number of services that help in reducing the risk, controls the quality and then verifies quantity along with meeting up the regulatory requirements. Any product is usually inspected a number of times during its life cycle to ensure that it is designed and efficiently operated along with meeting the set benchmark for quality and safety. The companies involved in inspection services UAE offer their clients that the products they have installed in their setups comply with the local and international benchmarks and function as per the given requirements. The inspection companies in Abu Dhabi mostly deal with a wide range of products including the Lifting Equipment like cranes, moving equipment, workshop equipment, vehicles, and machines. You can hire companies dealing with inspection services in UAE.